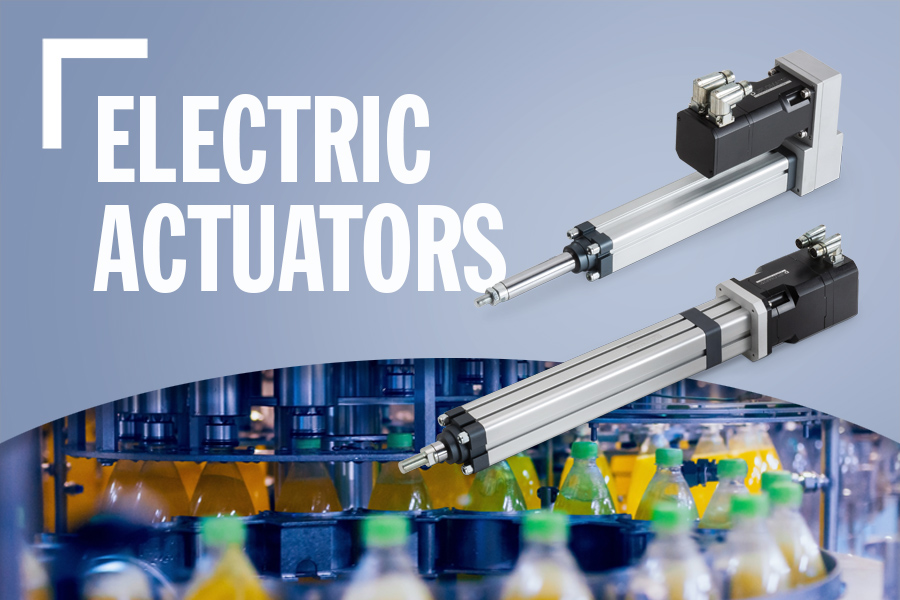

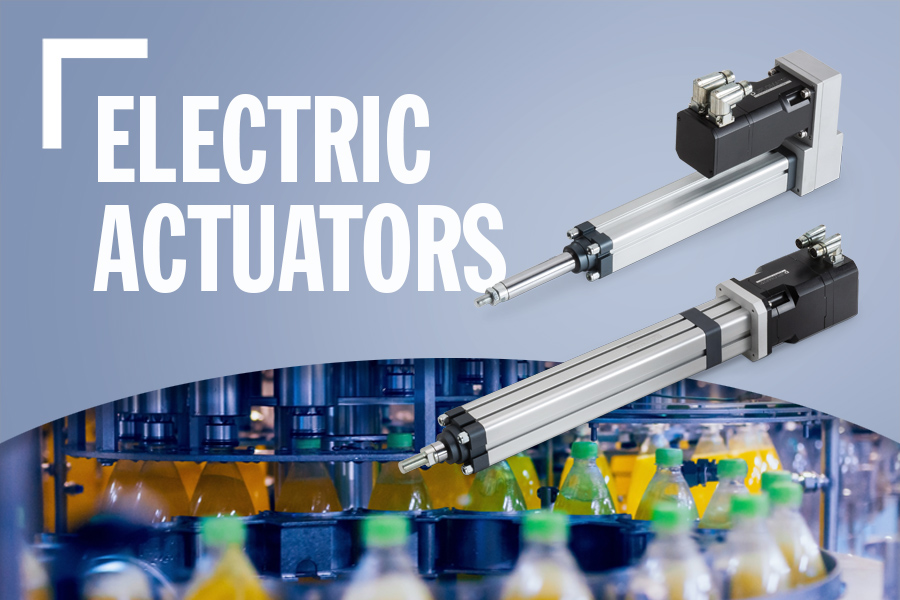

Flexing our electronic muscles

Flexibility of electric actuators brings added value in terms of power saving. Electric cylinder consumes one tenth the power absorbed by a pneumatic one. Including an increase in productivity, thanks to reduction of working times and production downtime’s. Plus smart controls and versatility. Hygienic clean design for applications in clean rooms and food and beverage machines.

Air pipes are, in fact, replace by electric cables, without the need for manifolds and FRL (filter regulator lubricator) groups. The electric actuators produce customized solutions, even for a single piece and offers the possibility to fit customers’ motors on the cylinders. Other benefits in term of flexibility are the wide range of motors available, the three types of bearing stacks depending on the application, the different types of screws for motion transmissions. All cylinders can be equipped

with in-line or parallel motors.