Dual Monitored Valves / Kits

• TÜV Certification

• Safety components in accordance with EN 692, ISO 13849-1 and -2

• Meets up to Category 4, PLe, SIL3 requirements

• Rated to IP66 for high pressure wash-down

These redundant design products, when properly implemented into the safety control and monitoring system using a high diagnostic coverage, can achieve Category 4, SIL 3 coverage requirements.

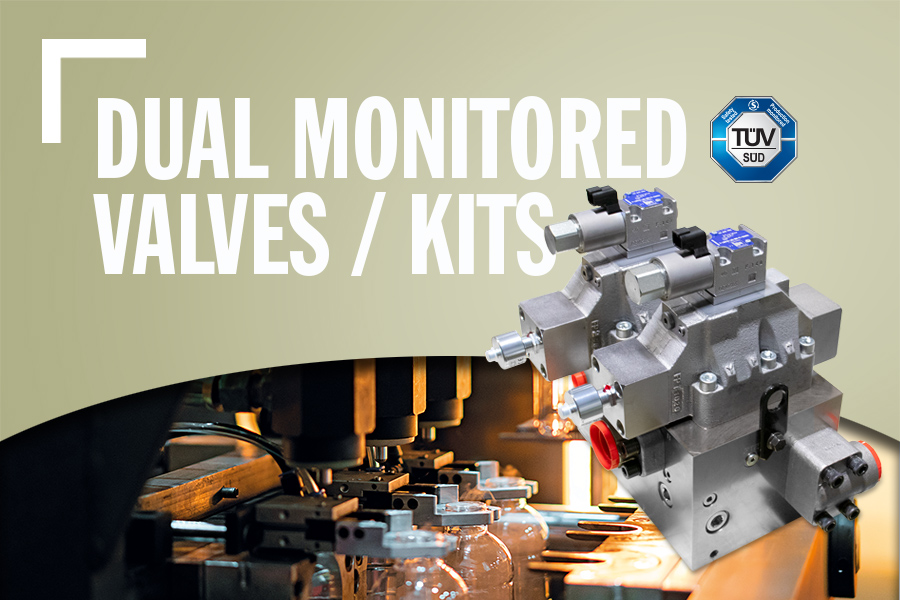

Dual monitored kits consist of ductile iron manifold and two single solenoid valves making it a redundant design. The series – parallel circuit design blocks flow and pressure until both valves have been actuated to allow flow and pressure from the supply to the machine. If either valve is deactivated the flow to the outlet port will be blocked from the hydraulic supply source and the outlet port is then automatically connected to tank removing all potential hydraulic power at the machine.

The solenoid operated directional valves are equipped with position sensors that monitor the main spool position. The switching position is indicated by a binary signal.

Continental Hydraulics double redundant valve assemblies are ideal for applications such as:

• Brick and Block Manufacturing

• Automotive Assembly Lines

• Machining Centers

• Recharging Systems in Critical Petro-Chemical/Energy Producing Applications

• Pulp and Paper Product Production

• Saw Mills

• Metal Forming

• Food Processing Plants

• Powering Dam Gates

• Motion Simulators

• Hydraulic Presses